Ever feel like your car is trying to tell you something? It might be whispering secrets through its wheel studs. That's right, those seemingly insignificant metal pegs hold the key to a world of automotive knowledge. We're talking about wheel stud spacing, aka bolt pattern or PCD (pitch circle diameter), and it's more important than you think.

So, what exactly is this wheel stud spacing business? It's the precise measurement that dictates how your wheels mount to your car. Getting this right is like finding the perfect pair of shoes – essential for comfort, performance, and avoiding some seriously awkward situations (imagine a wheel falling off!). Ignore it, and you risk a bumpy ride, premature wear and tear, and even dangerous handling issues.

The history of standardized wheel stud spacing is surprisingly intertwined with the rise of mass-produced automobiles. As cars became more common, the need for interchangeable parts, including wheels, became paramount. This led to the development of standard bolt patterns, allowing wheels from different manufacturers to fit a range of vehicles. Without these standards, the automotive world would be a chaotic mess of incompatible parts.

Why should you care about measuring wheel stud spacing? It’s not just about aesthetics. A mismatch between your wheel's bolt pattern and your car's hub can lead to vibrations, improper torque, and ultimately, wheel failure. Imagine cruising down the highway and suddenly losing a wheel – not a scenario anyone wants to experience. Accurate measurement ensures a secure and stable connection, keeping your ride smooth and safe.

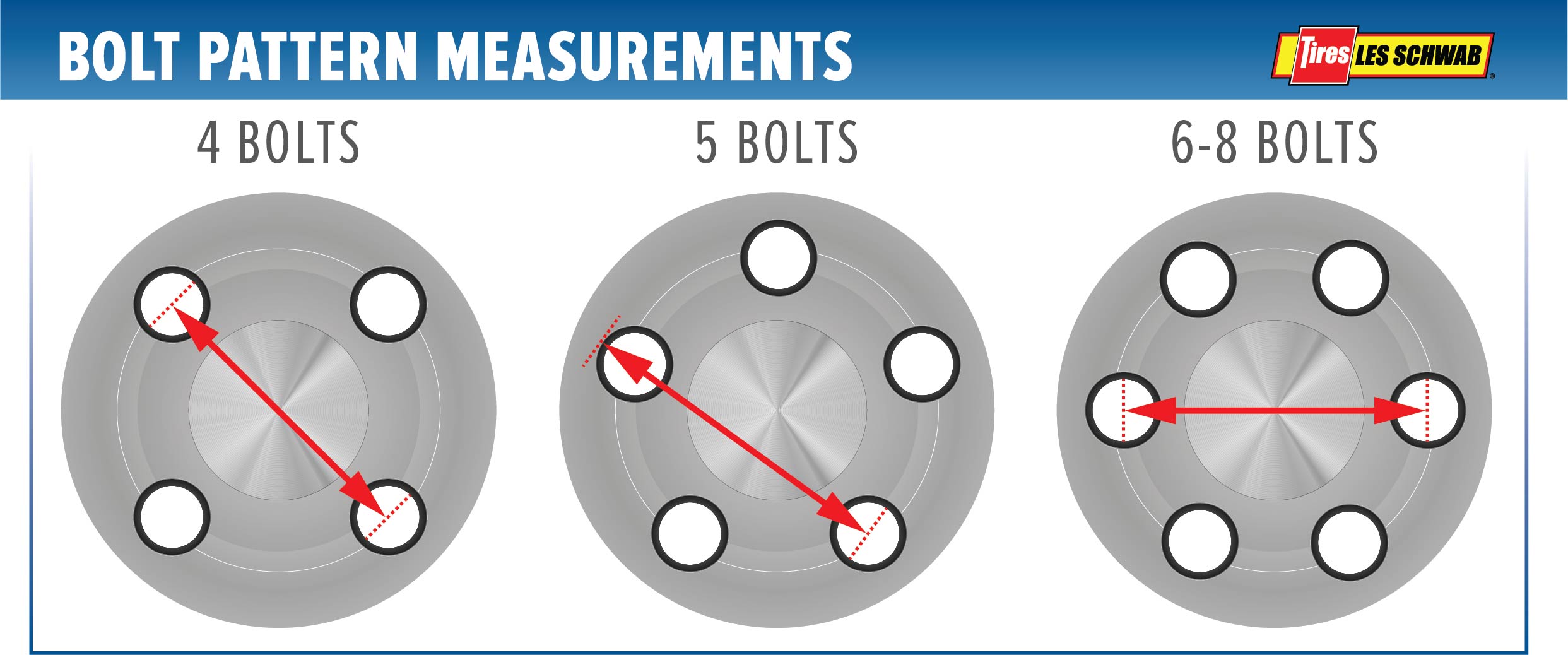

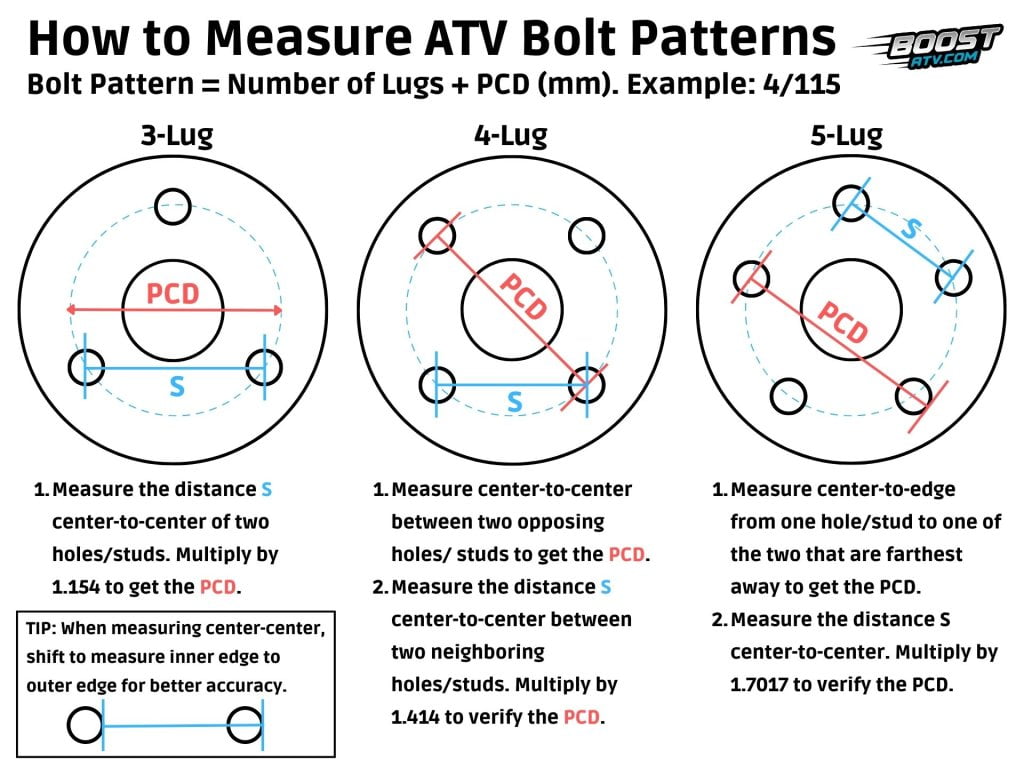

But how do you actually measure this mystical wheel stud spacing? There are several methods, ranging from simple rulers and calipers for 4 and 6-lug patterns to specialized tools for more complex setups. Accurately determining the PCD, the number of studs, and the center bore diameter is crucial for proper fitment. Misinterpreting these measurements can lead to purchasing the wrong wheels, a costly and frustrating mistake.

One of the most important aspects of determining wheel fitment is understanding how to measure wheel stud spacing. While seemingly straightforward, many car enthusiasts make common errors, from misidentifying the bolt pattern to neglecting the center bore. Understanding the specific requirements for different vehicles is vital for choosing the correct replacement wheels. For instance, a 5x114.3mm pattern doesn't automatically guarantee compatibility; the center bore and other factors must also be considered.

Benefit 1: Safety - Proper wheel stud spacing ensures that your wheels are securely attached to your vehicle, preventing them from coming loose while driving. Example: Imagine driving down the highway when suddenly your wheel detaches because the stud spacing was incorrect. This can lead to serious accidents.

Benefit 2: Performance - Correct wheel stud spacing allows your wheels to rotate smoothly and efficiently, improving your car's handling and performance. Example: If your wheels are not properly centered due to incorrect spacing, it can cause vibrations and affect your car's steering.

Benefit 3: Prevents Damage - Using wheels with the correct stud spacing prevents damage to your car's hubs, brakes, and suspension. Example: Using wheels with the wrong spacing can put stress on your car's components and lead to premature wear and tear.

Step-by-step guide to measuring 4 and 6 lug bolt patterns: 1. Measure from the center of one stud to the center of the opposite stud for a 4-lug pattern. 2. For a 6-lug pattern, measure from the center of one stud to the center of the stud directly across from it.

Advantages and Disadvantages of Precise Wheel Stud Spacing

| Advantages | Disadvantages |

|---|---|

| Improved Safety | Requires Precise Measurement |

| Enhanced Performance | Limited Wheel Choices if Incorrectly Measured |

| Reduced Wear and Tear | Potential for Costly Mistakes if Wrong Wheels are Purchased |

Best Practices: 1. Always double-check measurements. 2. Use the correct measuring tools. 3. Consult your vehicle's owner's manual. 4. Consult with a professional if unsure. 5. Compare measurements with online resources or databases.

FAQ: 1. What is wheel stud spacing? Answer: The distance between the mounting holes on a wheel. 2. Why is it important? Answer: For safety and proper fitment. 3. How do I measure it? Answer: Use a ruler, caliper, or dedicated tool. 4. What if the spacing is wrong? Answer: Wheels won't fit correctly. 5. Can I use adapters? Answer: Sometimes, but it's not always recommended. 6. What is PCD? Answer: Pitch Circle Diameter, another term for bolt pattern. 7. What's the center bore? Answer: The hole in the center of the wheel. 8. What if my center bore is too large? Answer: Hub-centric rings can be used.

Tips and tricks: Use a digital caliper for more precise measurements. Clean the wheel hub before measuring to remove any debris. Consult online forums or communities for specific vehicle information.

In conclusion, understanding and accurately measuring wheel stud spacing is crucial for both safety and performance. Don't underestimate the importance of this seemingly small detail. Correctly fitted wheels ensure a smooth, safe, and enjoyable driving experience. By taking the time to measure and confirm your vehicle's bolt pattern, you're investing in the longevity of your car and your own peace of mind. Remember, a few minutes spent measuring can prevent costly repairs and potentially dangerous situations down the road. So, the next time you're thinking about new wheels, remember the silent language of your car's studs, and take the time to measure – it’s an investment in your safety and your car's well-being. A properly fitted wheel is a happy wheel, and a happy wheel means a happy driver. So grab your measuring tools and unlock the secrets of your car's stud spacing today! You'll thank yourself later.

Navigating medicare supplement plans a smart approach

Exploring the world of bound by honor pdfs

Unveiling the colors of our solar system planets