Ever wondered how machines know when to stop? Or how a garage door reverses when it hits an obstacle? The answer often lies in a tiny but powerful component: the limit micro switch. These compact electrical switches are the unsung heroes of automation, providing precise control in countless applications. Understanding their wiring schemes is crucial for anyone working with automated systems, from DIY enthusiasts to industrial engineers.

Limit micro switches are essentially miniature snap-action switches activated by physical contact. They're designed to be tripped by a moving part, signaling a change in state within a system. This signal can then be used to stop a motor, reverse a process, or trigger another action. Imagine a 3D printer: limit switches ensure the print head doesn't overextend and damage the machine. Similarly, they're vital in robotic arms, conveyor belts, and even simple appliances like clothes dryers.

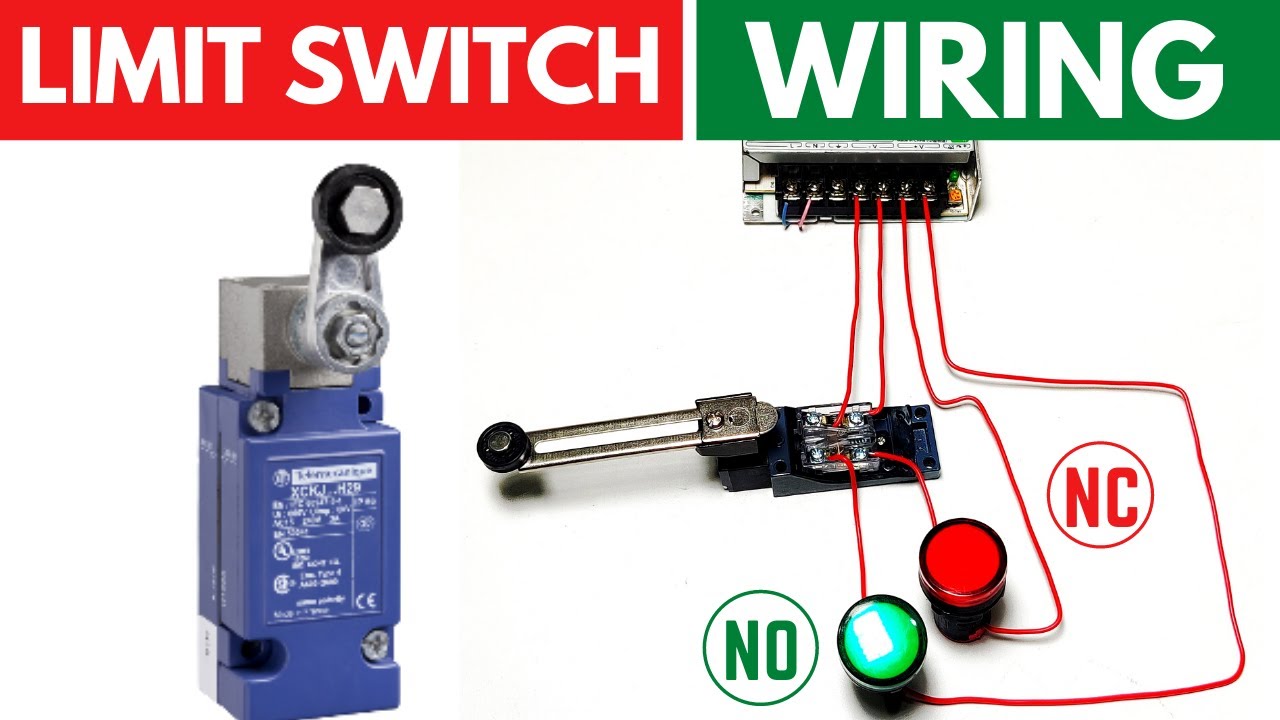

The wiring for these versatile components might seem daunting at first, but it's surprisingly straightforward once you grasp the basics. A typical limit switch circuit involves connecting the switch's common terminal to a power source, the normally open (NO) or normally closed (NC) terminal to the controlled device, and the other terminal to ground. The choice between NO and NC depends on whether you want the circuit to activate when the switch is pressed or released.

The history of the limit micro switch parallels the rise of automation. As machinery became more complex, the need for precise control grew. Early limit switches were bulky and prone to failure, but advancements in materials and design led to the compact, reliable devices we use today. This evolution has been crucial for industries ranging from manufacturing and robotics to aerospace and automotive.

One of the main challenges in implementing limit switch circuits is ensuring proper placement and adjustment. If the switch isn't positioned correctly, it might not trigger at the desired point, leading to malfunctions or even damage. Incorrect wiring can also cause issues, such as short circuits or failure to activate the controlled device. Troubleshooting these problems often involves checking the wiring diagram, testing the switch's continuity, and verifying the power supply.

A simple example of a limit micro switch application is a garage door opener. When the door reaches its fully open position, a limit switch is triggered, cutting power to the motor and preventing further movement. Similarly, when the door closes completely, another switch activates, stopping the motor and preventing damage.

Three key benefits of incorporating limit micro switches into automated systems are enhanced safety, improved precision, and increased efficiency. Safety is paramount, and limit switches play a vital role in preventing accidents by stopping machinery before it reaches dangerous limits. Precision is achieved by ensuring actions occur at precise points, crucial for tasks like robotic assembly. Efficiency gains come from automating repetitive tasks and preventing errors that can lead to wasted time and resources.

Creating an action plan for implementing limit switches involves defining the application, selecting the appropriate switch type, designing the wiring diagram, and testing the circuit thoroughly. A successful example is the use of limit switches in CNC machines, where they precisely control the movement of cutting tools, resulting in accurate and repeatable parts.

Advantages and Disadvantages of Limit Micro Switches

| Advantages | Disadvantages |

|---|---|

| Simple and easy to install | Can be prone to wear and tear with repeated use |

| Cost-effective solution for automation | Limited lifespan compared to other sensor technologies |

| Reliable and durable in many applications | Sensitivity to environmental factors like dust and moisture |

Best practices for implementing limit micro switches include selecting the correct switch for the application, ensuring proper mounting and alignment, using appropriate wiring techniques, and implementing safety measures such as emergency stops.

Real-world examples of limit switch use include controlling the travel of elevators, limiting the range of motion in robotic arms, triggering safety shutdowns in industrial machinery, activating automatic door openers, and regulating the flow of materials in conveyor systems.

Challenges in using limit micro switches can include mechanical wear, electrical noise, environmental factors, and improper installation. Solutions involve regular maintenance, shielding against electrical interference, using sealed switches in harsh environments, and following proper wiring diagrams.

FAQs:

Q: What is a limit micro switch?

A: A small, snap-action switch activated by physical contact, used to control the limits of movement in a system.

Q: How does a limit switch work?

A: When a moving part makes contact with the switch's actuator, it triggers an internal mechanism, changing the state of the electrical circuit.

Q: What are NO and NC contacts?

A: NO (normally open) contacts close the circuit when the switch is activated. NC (normally closed) contacts open the circuit when the switch is activated.

Q: How do I wire a limit switch?

A: Connect the common terminal to power, the NO or NC terminal to the controlled device, and the remaining terminal to ground.

Q: How do I troubleshoot a limit switch circuit?

A: Check the wiring, test the switch's continuity, and verify the power supply.

Q: What are some common applications of limit switches?

A: Garage door openers, industrial machinery, robotics, elevators, and conveyor systems.

Q: How do I choose the right limit switch?

A: Consider factors like actuator type, operating force, electrical rating, and environmental conditions.

Q: How do I maintain a limit switch?

A: Regularly inspect for wear and tear, clean contacts, and lubricate moving parts as needed.

Tips and tricks for working with limit switches include using shielded cables to reduce electrical noise, mounting the switch securely to prevent false triggering, and testing the circuit thoroughly after installation.

In conclusion, limit micro switches are essential components in countless automated systems, offering precise control, enhanced safety, and increased efficiency. Understanding their wiring diagrams, applications, and troubleshooting techniques is crucial for anyone working with these versatile devices. From simple household appliances to complex industrial machinery, limit switches play a vital role in ensuring smooth operation and preventing malfunctions. By mastering the principles of limit switch wiring and implementing best practices, you can unlock the full potential of these small but powerful components. Explore further resources, like online tutorials and technical manuals, to deepen your knowledge and stay ahead in the world of automation. As technology advances, limit switches will continue to be a cornerstone of control systems, making it even more crucial to understand their workings. Take the time to learn, experiment, and unlock the potential of limit micro switches in your own projects and endeavors.

Unlocking the perfect 3 pound roast beef at 350

Ecumenical councils shaping christian history

Cobblestone landscaping ideas for a charming outdoor space