Ever wondered about those mysterious numbers and letters associated with your car's wheels? They represent the wheel bolt pattern, a crucial piece of information for anyone looking to replace or upgrade their rims. Getting this measurement right is paramount for safe and proper wheel fitment. A mismatched bolt pattern can lead to vibrations, damage to your vehicle, and even dangerous driving conditions. This guide will demystify the process of measuring your wheel bolt pattern, empowering you to make informed decisions about your car’s wheels.

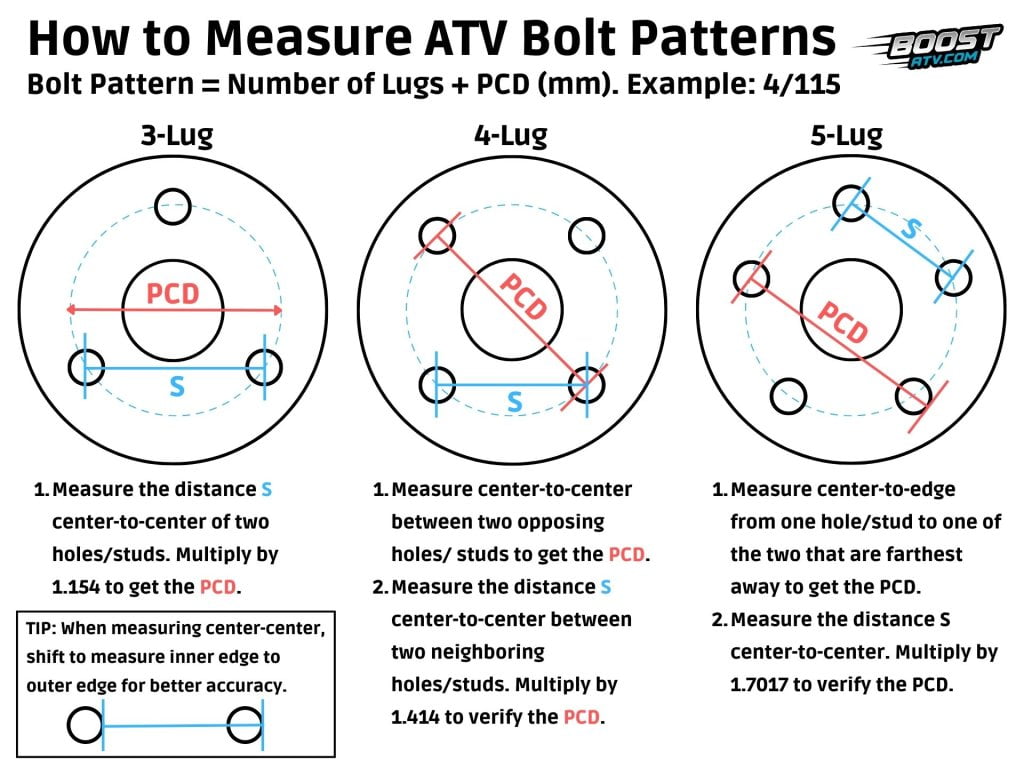

Understanding your vehicle’s wheel bolt pattern, often referred to as PCD (Pitch Circle Diameter) or bolt circle, is fundamental to ensuring proper wheel fitment. This measurement determines the arrangement and spacing of the lug holes on your wheel hub, which must precisely match the bolt pattern on your new wheels. Without accurate measurement, you risk purchasing wheels that simply won't fit. So, how do you decipher this critical code?

The concept of a standardized wheel bolt pattern arose with the mass production of automobiles. Early vehicles often had bespoke wheel designs, making replacements difficult and expensive. The standardization of bolt patterns streamlined the process, allowing for interchangeability and a wider selection of aftermarket wheels. The evolution of wheel bolt pattern measurement tools has also mirrored this progression, moving from rudimentary manual measurements to sophisticated digital tools.

One of the primary issues with measuring wheel bolt patterns is the potential for inaccuracy. Using improper techniques or worn-out measuring tools can lead to incorrect readings. Even a small discrepancy can cause significant problems. Imagine driving with wheels that aren't properly secured – a terrifying thought. Therefore, using the correct wheel bolt pattern gauge or measurement technique is essential.

A wheel bolt pattern is usually expressed as two numbers separated by a letter. For example, 5x114.3 indicates five lug holes with a pitch circle diameter of 114.3 millimeters. Various tools exist to accurately determine these measurements, ranging from simple rulers and calipers to specialized wheel bolt pattern measurement tools. These specialized tools, often designed with sliding calipers and clear markings, simplify the measurement process and reduce the risk of errors.

One benefit of using a dedicated wheel bolt pattern measurement tool is increased accuracy. These tools are specifically designed for the task, providing more precise readings compared to general-purpose measuring devices. For example, a digital wheel bolt pattern gauge can provide measurements down to the millimeter, eliminating guesswork and ensuring a perfect fit. Another advantage is ease of use. These tools are typically user-friendly, even for novice car enthusiasts. Clear markings and intuitive designs simplify the process, making it quick and easy to obtain accurate measurements. Finally, using a proper tool saves time. Compared to manual methods which can be tedious and error-prone, a dedicated tool streamlines the process, allowing you to determine your bolt pattern quickly and efficiently.

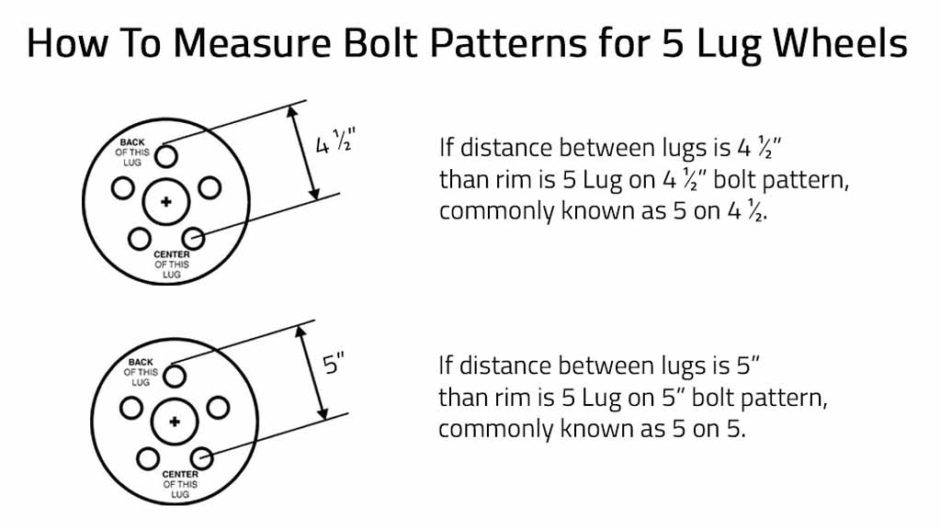

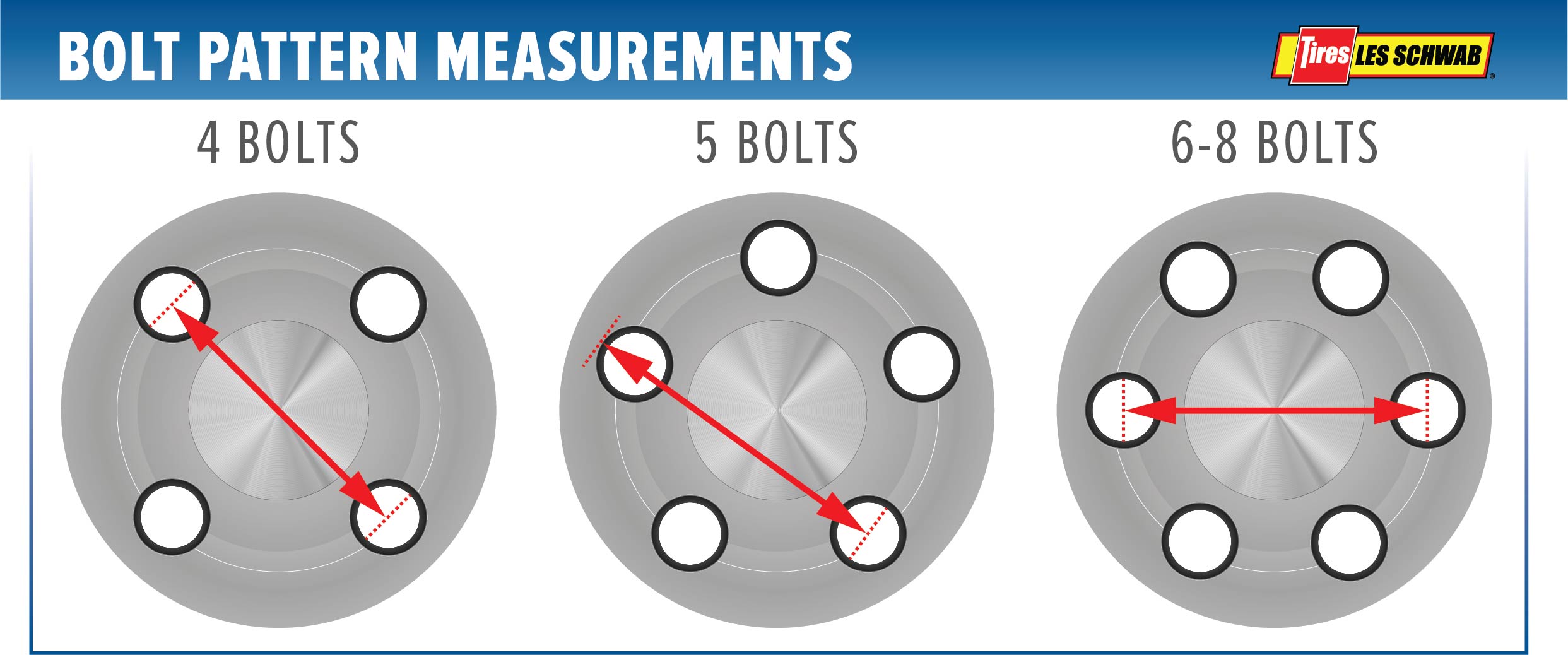

To accurately measure your wheel bolt pattern, first ensure the wheel is clean and free of debris. Next, identify the number of lug holes. Then, use your chosen wheel bolt pattern measurement tool, be it a dedicated gauge or a combination of ruler and caliper, to measure the distance between two adjacent lug holes (for 4 and 6-lug patterns) or opposite lugs (for 5-lug patterns). Refer to online resources or the tool's instructions for specific measurement procedures based on the number of lugs.

Advantages and Disadvantages of Dedicated Wheel Bolt Pattern Measurement Tools

| Advantages | Disadvantages |

|---|---|

| Increased Accuracy | Can be more expensive than basic tools |

| Ease of Use | May not be necessary for infrequent use |

| Saves Time | Requires proper storage to prevent damage |

Best practices for implementing a wheel bolt pattern measurement tool include: ensuring the tool is properly calibrated, cleaning the wheel hub surface before measurement, taking multiple measurements for accuracy, consulting the vehicle’s owner manual for factory specifications, and double-checking measurements with a trusted mechanic or tire shop.

Real-world examples of wheel bolt pattern measurements include 5x114.3 (common on Japanese and Korean vehicles), 5x120 (common on BMW vehicles), 4x100 (common on small cars), and 6x139.7 (common on trucks and SUVs).

One challenge in using these tools can be accessing the wheel hub due to rust or debris. The solution is to thoroughly clean the hub before measuring. Another challenge might be interpreting the measurements on certain tools. The solution is to refer to the tool's instructions or consult online resources.

FAQs: What is a wheel bolt pattern? How do I measure it? What tools do I need? Why is it important? What happens if I use the wrong bolt pattern? Where can I find my car's bolt pattern information? What are the different types of wheel bolt pattern measurement tools? How do I choose the right tool for my needs?

Tips and tricks for using wheel bolt pattern measurement tools include: taking measurements from multiple points for greater accuracy, using a digital caliper for more precise readings, and consulting online forums or communities for advice and tips specific to your vehicle's make and model.

In conclusion, understanding and accurately measuring your wheel bolt pattern is paramount for safe and proper wheel fitment. A correctly measured bolt pattern ensures a secure connection between your wheels and your vehicle, preventing potentially dangerous driving situations. From basic rulers and calipers to sophisticated digital gauges, various wheel bolt pattern measurement tools are available to suit different needs and budgets. By utilizing the right tools and techniques, you can confidently select new wheels that fit perfectly, enhancing both the appearance and safety of your vehicle. Taking the time to accurately measure your wheel bolt pattern is a small investment that pays off significantly in terms of safety, performance, and peace of mind. Don't leave your wheel fitment to chance; empower yourself with the knowledge and tools to make the right choice. Start by checking your owner's manual or consulting a reputable tire shop to begin your journey towards a perfect wheel fit.

Winning nfl bets free picks against the spread today

Toyota corolla deciphering the p0171 code mystery

Unleash your inner artist the power of simple skull drawings