The subtle art of creating hydrochloric acid, a compound as essential as it is potent, is a journey into the heart of chemical synthesis. It's a process that demands precision, respect, and a thorough understanding of the underlying chemical reactions. This exploration into the creation of HCl will unravel the complexities and reveal the significance of this powerful acid.

Producing hydrochloric acid is not a casual undertaking. The process necessitates careful consideration of safety protocols, precise measurements, and an awareness of the potential hazards. From the initial selection of reactants to the final storage of the product, each step plays a crucial role in ensuring both the efficacy and safety of the process.

The creation of hydrochloric acid is a testament to human ingenuity, a manipulation of the fundamental building blocks of matter. It's a dance between elements, orchestrated by precise calculations and controlled reactions. Understanding the history of this process, from its early alchemical origins to modern industrial production, gives us a greater appreciation for the complexities involved.

The hydrochloric acid creation process intersects with many industries, from metal refining to food processing. Its versatility speaks volumes about its inherent properties. But this versatility also underscores the importance of responsible handling and usage. Generating hydrochloric acid is a responsibility, a commitment to safe practices and ethical application.

Synthesizing hydrochloric acid is an intriguing blend of science and artistry. It involves careful monitoring of reactions, adjustments based on observations, and a respect for the potent nature of the resulting compound. This article delves into the process, highlighting the various methods and the critical safety measures required.

Historically, hydrochloric acid was produced by heating salt (sodium chloride) with sulfuric acid. This method, developed in the Middle Ages, laid the foundation for modern HCl production techniques. The importance of hydrochloric acid lies in its myriad applications, including cleaning, pickling steel, and pH control. A main issue associated with producing hydrochloric acid is safety, due to the corrosive nature of both the reactants and the product.

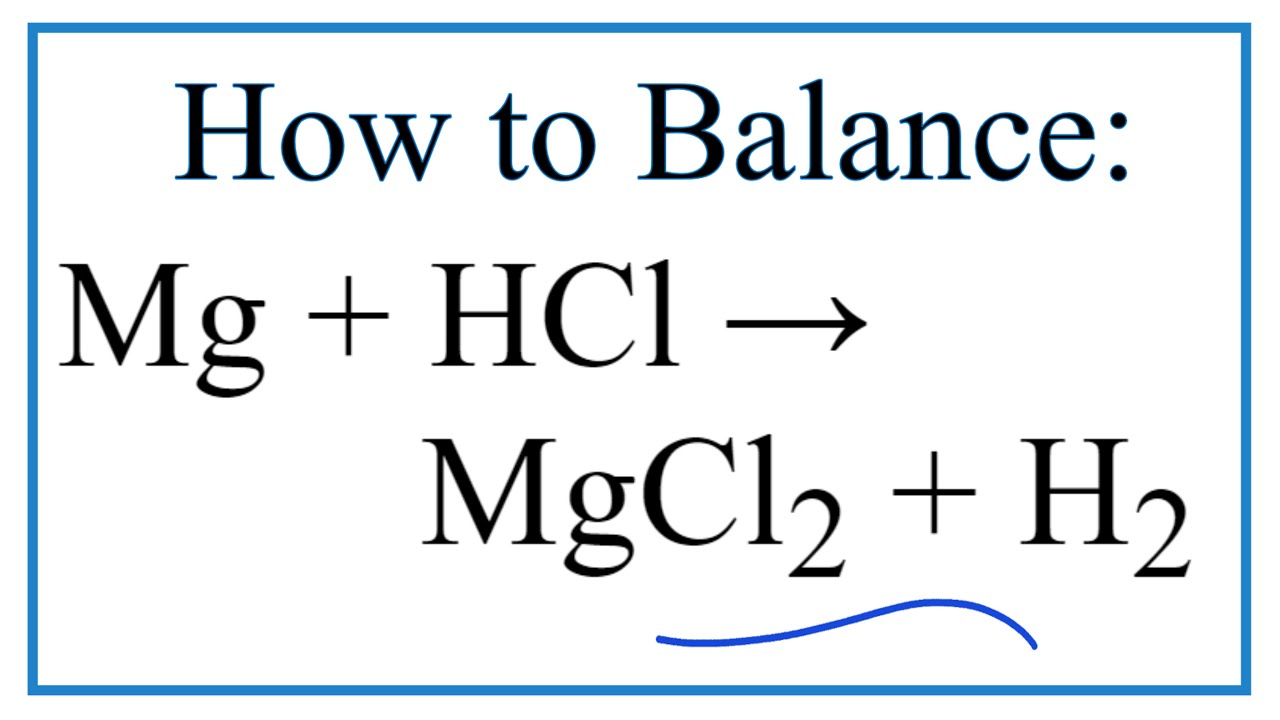

Hydrochloric acid is a strong acid, meaning it completely dissociates in water, releasing hydrogen ions (H+) and chloride ions (Cl-). A simple example of its use is in cleaning metal surfaces, where the acid reacts with rust and other impurities, dissolving them.

One benefit of producing your own hydrochloric acid (in controlled industrial settings) is the potential cost savings. Another benefit is having immediate access to the acid when needed. Finally, specific concentrations can be tailored to meet particular industrial needs.

Due to the hazardous nature of producing hydrochloric acid, detailed step-by-step instructions and a checklist are not provided. This information should only be accessed and implemented by trained professionals in controlled laboratory or industrial settings.

Advantages and Disadvantages of Hydrochloric Acid Production

| Advantages | Disadvantages |

|---|---|

| Cost-effective (in industrial settings) | Hazardous reactants and product |

| On-demand availability (in industrial settings) | Requires specialized equipment and expertise |

| Control over concentration (in industrial settings) | Stringent safety protocols necessary |

For detailed information regarding the production of hydrochloric acid, consult specialized chemical engineering resources and textbooks. Always prioritize safety and consult with experienced professionals before handling any chemical reactions involving strong acids.

Frequently Asked Questions: What are the safety precautions? (Consult a safety data sheet). What are the common uses? (Cleaning, pickling, pH control). What is the chemical formula? (HCl). What concentration is typically used? (Varies depending on the application). What are the storage requirements? (Store in a cool, dry, well-ventilated area). How do you neutralize hydrochloric acid? (Carefully add a base like sodium bicarbonate). What are the first aid procedures for acid exposure? (Flush affected area with water immediately and seek medical attention). What are the environmental concerns? (Proper disposal is crucial to prevent environmental contamination).

A crucial tip when working with hydrochloric acid is to always add acid to water, never the reverse. This prevents splashing and potential hazards.

In conclusion, producing hydrochloric acid is a complex process requiring careful consideration of safety protocols and a deep understanding of chemical reactions. While the benefits, such as cost savings and tailored concentrations, are attractive in industrial settings, the inherent dangers necessitate rigorous safety measures. The creation of HCl is a powerful demonstration of chemical synthesis, but it's a power that must be wielded with responsibility and respect. Always prioritize safety, consult reliable resources, and seek guidance from experienced professionals before undertaking any processes involving strong acids. Understanding the history, applications, and potential hazards is crucial for anyone involved in the production or use of hydrochloric acid. It is a testament to human ingenuity, a tool with far-reaching applications, and a substance that demands respect and careful handling.

Celebrating a decade crafting unforgettable 10 year old birthday experiences

Dive into the soothing depths of blue green color palettes

Unlocking the 5x100 wheel bolt pattern mystery your rides secret code