Imagine this: a perfect sunset, the gentle lapping of water against your dock, and your boat… stuck halfway in the water because your lift motor isn’t working. A frustrating scenario, right? But one that's often easily avoided with a solid understanding of how to wire your boat lift motor and switch correctly.

Wiring a boat lift motor might seem daunting at first, like a tangled mess of wires waiting to zap you. But with a bit of patience and the right knowledge, it’s a manageable task that can save you time, money, and a lot of future headaches. This comprehensive guide breaks down the process, offering a roadmap to navigate the complexities of boat lift motor wiring. From the basic principles to troubleshooting tips, we’ll cover everything you need to know to get your boat lift running smoothly.

The ability to control the movement of a boat lift is essential for its proper function. This control comes from the correct connection of the motor to a power source and the proper installation of a switch to manage that power. Getting these connections right is paramount for safety and the long-term operation of your lift.

Historically, boat lifts were simpler mechanisms, often manually operated. As technology advanced, electric motors became the standard, allowing for easier and more convenient boat lifting. With this advancement came the need for proper wiring. Incorrect wiring can lead to a range of problems, from blown fuses to motor damage, and even pose safety risks.

The key is to understand the components involved. Your boat lift motor is the muscle, providing the power to raise and lower the lift. The switch acts as the brain, directing the flow of electricity to the motor. Connecting these two components correctly ensures they work in harmony, allowing you to control your boat lift effortlessly.

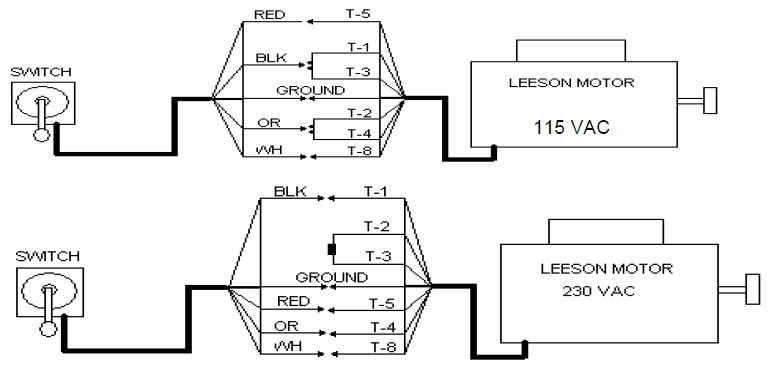

A simple boat lift motor wiring setup generally involves a double-pole double-throw (DPDT) switch, which allows for reversing the motor's direction to raise and lower the lift. The switch connects to the motor and the power source, creating a circuit that allows electricity to flow when the switch is flipped. Understanding the wiring diagram for your specific motor and switch is crucial for successful installation.

One benefit of properly wiring your boat lift motor and switch is safety. Correct wiring minimizes the risk of electrical shocks and short circuits, protecting both you and your equipment. Another advantage is the improved longevity of your motor. Correct wiring ensures the motor operates efficiently, reducing wear and tear and extending its lifespan.

Before you start, gather your materials: the motor, the switch, appropriate wiring, wire connectors, and tools like wire strippers and screwdrivers. Next, disconnect the power supply to ensure safety. Then, follow the wiring diagram for your specific motor and switch, carefully connecting the wires and securing them with connectors. Finally, test the connections to ensure everything is working as expected.

Advantages and Disadvantages of DIY Wiring vs. Professional Installation

| Feature | DIY Wiring | Professional Installation |

|---|---|---|

| Cost | Lower upfront cost | Higher upfront cost |

| Time | Can be time-consuming | Faster completion |

| Risk | Higher risk of errors and safety issues | Lower risk of errors and safety issues |

Best Practices:

1. Always disconnect the power before working on any electrical connections.

2. Use marine-grade wiring and connectors to resist corrosion.

3. Consult the wiring diagram specific to your motor and switch.

4. Secure all connections properly to prevent loosening.

5. Test the wiring thoroughly before reconnecting the power.

FAQ:

1. What type of wire should I use? Marine-grade wire is recommended for its corrosion resistance.

2. What is a DPDT switch? A DPDT switch allows for reversing the motor's direction.

3. Do I need a permit to wire a boat lift motor? Check local regulations as requirements vary.

4. What gauge wire should I use? Consult your motor's specifications for the recommended wire gauge.

5. Can I use regular household wire? No, marine-grade wire is required for boat lift applications.

6. What if my motor doesn't work after wiring? Double-check all connections and consult the wiring diagram.

7. Where can I find a wiring diagram? Check your motor and switch manuals or contact the manufacturer.

8. Is it safe to wire a boat lift motor myself? If you are comfortable with electrical work, it can be done safely by following proper procedures.

Tips and Tricks: Label all wires clearly for easier troubleshooting. Use heat shrink tubing to protect wire connections from moisture.

Understanding how to wire your boat lift motor and switch is a crucial aspect of boat ownership. It ensures the smooth operation of your lift, extends the life of your motor, and most importantly, enhances safety. While it may seem complex initially, by following this guide and taking your time, you can successfully wire your boat lift and enjoy the convenience and peace of mind it provides. Don’t let the fear of wiring keep you from enjoying your time on the water. Take the time to learn, and you’ll be rewarded with a smoothly functioning boat lift for years to come. Remember to always prioritize safety and consult with a professional if you have any doubts. A little knowledge and effort can go a long way in making your boating experience safer and more enjoyable.

Immersive soundscapes exploring the world of wet sounds audio systems

Finding your place exploring rental opportunities in bukit jelutong

Unlocking your cars bolt pattern a surprisingly simple guide