Ever stared at a wheel, wondering what secrets its bolt pattern held? It's more than just holes; it’s the key to compatibility, performance, and that perfect flush fitment. Knowing how to identify a wheel's bolt pattern is crucial for anyone looking to replace or upgrade their wheels.

The bolt pattern, also known as the lug pattern or PCD (Pitch Circle Diameter), defines the arrangement of the lug holes on a wheel. It dictates which wheels will fit your vehicle and ensures safe and proper installation. Ignoring this critical detail can lead to vibrations, premature wear on suspension components, and even wheel detachment – a scenario no driver wants to experience. Think of it as the handshake between your wheel and your car; it has to be just right.

Determining a wheel bolt pattern isn't rocket science. It involves measuring the distance between lug holes in a specific way, depending on whether you have an even or odd number of lugs. But before we delve into the how-to, let's take a brief look at why this seemingly simple set of numbers holds so much importance.

Historically, wheel bolt patterns have evolved alongside automotive engineering, adapting to changes in vehicle weight, performance demands, and manufacturing processes. Early cars often featured simple four-lug patterns, while modern vehicles frequently utilize five, six, or even eight lugs for increased load-bearing capacity and stability, especially in trucks and SUVs. This evolution underscores the importance of accurate bolt pattern identification.

One of the primary issues surrounding wheel bolt patterns is the sheer variety available. Different manufacturers and even different models within the same brand can have varying bolt patterns. This makes understanding how to decode your specific bolt pattern crucial for avoiding costly mistakes and ensuring a safe and proper fit.

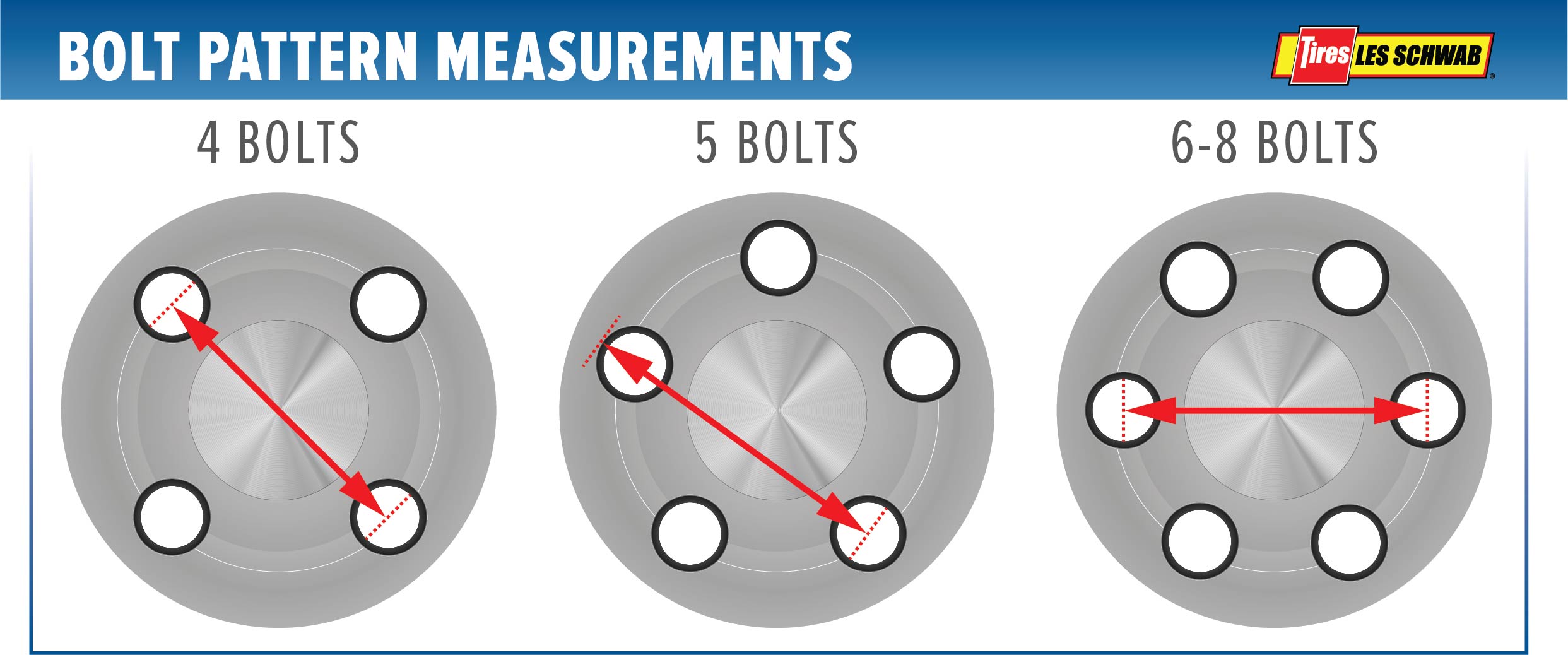

Identifying a wheel's bolt pattern involves measuring the center-to-center distance between lug holes. For wheels with an even number of lugs (like four or six), measure from the center of one lug hole directly across to the center of the opposite lug hole. This is your bolt pattern. For wheels with an odd number of lugs (like five), the process is slightly different. You need to measure from the back edge of one lug hole to the center of the opposite lug hole. Then multiply that measurement by 1.051 to get the PCD.

Understanding your wheel bolt pattern offers several benefits. First, it ensures proper fitment, preventing vibration and potential damage. Second, it expands your wheel options, allowing you to choose from a wider range of aftermarket styles and designs. Third, knowing your bolt pattern empowers you to make informed decisions, avoiding compatibility issues and potentially dangerous situations.

Action Plan for Determining Your Bolt Pattern:

1. Locate the number of lug holes on your wheel.

2. If the number is even, measure directly across from one lug hole center to the opposite lug hole center.

3. If the number is odd, measure from the back edge of one lug hole to the center of the opposite lug hole, then multiply by 1.051.Advantages and Disadvantages of Knowing Your Wheel Bolt Pattern

| Advantages | Disadvantages |

|---|---|

| Ensures proper wheel fitment | Requires some measurement and calculation |

| Expands wheel choices | Potential for mismeasurement if not careful |

| Increases safety |

Best Practices:

1. Always double-check your measurements.

2. Use a precise measuring tool like a caliper.

3. Consult your vehicle's owner's manual or a reputable online database.

4. Verify the bolt pattern with the wheel seller before purchasing.

5. If in doubt, consult a professional.FAQs 1. What happens if I use the wrong bolt pattern? Vibrations, premature wear, and potential wheel detachment. 2. Where can I find my car's bolt pattern? Owner's manual, online databases, or a tire shop. 3. Can I change my car's bolt pattern? Generally, no, without extensive modifications. 4. Are there adapters for different bolt patterns? Yes, but they are not always recommended due to potential safety concerns. 5. Do all cars have the same bolt pattern? No, bolt patterns vary widely. 6. How accurate do my measurements need to be? Very accurate, within a few millimeters. 7. Can I measure the bolt pattern on a mounted wheel? Yes, but it can be more challenging. 8. What tools do I need to measure bolt pattern? A ruler or caliper.

Tips and Tricks: Clean the wheel hub face before measuring for more accurate results. Take multiple measurements and compare them for consistency.

In conclusion, understanding how to decipher your wheel bolt pattern is essential for any car owner. This seemingly small detail plays a significant role in ensuring safety, proper fitment, and maximizing your wheel options. By following the steps outlined in this guide, you can confidently navigate the world of wheel bolt patterns, avoiding costly mistakes and ensuring a smooth ride. Don't underestimate the power of this crucial piece of information; it's the foundation of a secure and stylish wheel setup. Take the time to learn your vehicle's bolt pattern – it's an investment in your safety and the longevity of your car. Empower yourself with the knowledge to make informed decisions about your wheels and experience the difference it makes in your driving experience. Don't just bolt on any wheel; make sure it's the right fit for a safe and stylish ride.

Ace hardware paint sale refresh your space for less

Cracking the code your california drivers test companion

That pesky corolla check engine light is it just the gas cap